What role do industrial pumps play in today’s industry?

The use of pumps is becoming ever more frequent in today’s industry. When the time comes to choose the most appropriate type of pump, a successful choice will depend on different factors such as the criticality of the process, the hours needed to pump or the physical data of the pumping including the type of fluid to be pumped, flow, pressure, temperature and elevation.

At we have taken into account all the specifications of industrial pumps to offer our customers the best offer in terms of quality, price and performance. In this article, you will find information about what an industrial pump is and the different types available.

What is an industrial pump and how does it work?

An industrial pump is a machine that transforms the mechanical energy it absorbs from an electric, thermal or other kinds of motor, and transfers it to a fluid as hydraulic energy. This allows the fluid to be transported from one place to another, on one level or different levels.

The operation of an industrial pump is simple: the inlet tube of the pump sucks the water and then is driven by a motor that uses coils and magnets to create a magnetic field, which gets the impeller to rotate continuously.

There are two large groups of industrial pumps: firstly we have the dynamic ones, among which are centrifuges, peripheral and special pumps; and secondly, we have the positive displacement ones, which we can be grouped into reciprocating and rotating.

Centrifugal pumps are the most widely used kind of hydraulic pump within the industry, as they are used to pump liquids in general and allow large amounts of water to be moved.

Next, we will describe the types of industrial pumps:

Types of Industrial Pumps currently on the market :

1. Centrifugal Pumps:

These pumps are the most used in the chemical industry and the most effective for handling solid particles carried in a fluid suspension. The centrifugal pump is a type of hydraulic pump that transforms the mechanical energy of an impeller into kinetic or pressure energy of an incompressible fluid. From mechanic to hydraulic.

The chemical and processing industries use centrifugal pumps for things like paints, chemicals, petrochemicals, pharmaceuticals, hydrocarbons, cellulose, food production, beverages and sugar refining…

The main characteristics of these pumps are:

1. They do not have articulated components and the coupling mechanisms are very simple.

2. The electric impeller of the motor is quite simple.

3. For a defined operation, the expense is constant and no regulating device is required.

4. They adapt easily to many circumstances.

5. The space required is about 1/8 of the equivalent plunger pump.

6. The weight is minimal, and therefore the foundations are too.

7. The maintenance of a centrifugal pump is reduced to changing the oil of the bearings, the packaging press – mechanical closure and sealing joints, so the number of elements to change is minimal.

8. The price of a centrifugal pump is ¼ of the price of an equivalent plunger pump.

2. Positive Displacement Pumps:

This type of industrial pump guides the fluid that moves along its entire trajectory, which is contained between the impeller and the housing or cylinder. They have a chamber that increases volume (suction) and decreases volume (drive). All types of rotary pumps are positive displacement pumps and include gear pumps, screw/spindle, rotating vanes and pistons.

3. Helical Pumps:

These pumps are known as progressive cavity pumps or helical screw pumps. They are positive displacement pumps and are ideal for the transfer of fluids with fragile solids. Suitable for viscous and abrasive fluids.

4. Liquid ring vacuum pumps

These pumps are positive displacement rotary machines that create a vacuum and are commonly used for all types of industrial processes in a wide range of industries including chemical, electrical, environmental, food and beverage processing and packaging, marine operations, mining and oil.

6. Lobe Pumps:

Lobe pumps are rotary volumetric pumps. Pumping is produced by 2 lobes that rotate in the opposite direction, to conduct the liquid into the space between the body and a lobe. The effect is smooth, with good acceptance of large particles in suspension.

5. Peristaltic Pumps:

The peristaltic pumps are a type of positive displacement hydraulic pump, used to pump a wide variety of fluids. The fluid is contained within a flexible tube recessed inside a circular cover of the pump so there is no contact between the mechanical elements and the product.

7. Flexible impeller pumps

Flexible impeller pumps are designed to work in both directions and are characterized by being self-priming and very versatile. However, they are not suitable for working at high temperatures (>80ºC) due to the high friction between the impeller and the body.

8. Rotary Pumps:

These industrial pumps discharge a continuous flow. Although they are generally considered pumps for viscous liquids, they can also handle almost any liquid that is free of abrasive solids. These are machines that develop pressure by transporting liquids in a defined path in a single direction. Some of the pumps mentioned above could also be included in this category although this term is generally used to talk about internal or external gear pumps.

9. Reciprocal or Alternative Pumps:

In these pumps, the fluid moves by alternative movement, when moving in one direction it sucks and in the opposite direction it expels. The best-known pump of this kind is the diaphragm.

InoxMIM is one of the leading manufacturers of centrifugal pumps nationwide, with high-performance machines and excellent results. In addition, our extensive experience allows us to offer the best pumping systems for the food, pharmaceutical, cosmetic and chemical industries.

We are committed to the needs of our customers, manufacturing pumps of different types that allow us to provide high-performance and quality pumping solutions for the chemical, food, cosmetic or pharmaceutical industries.

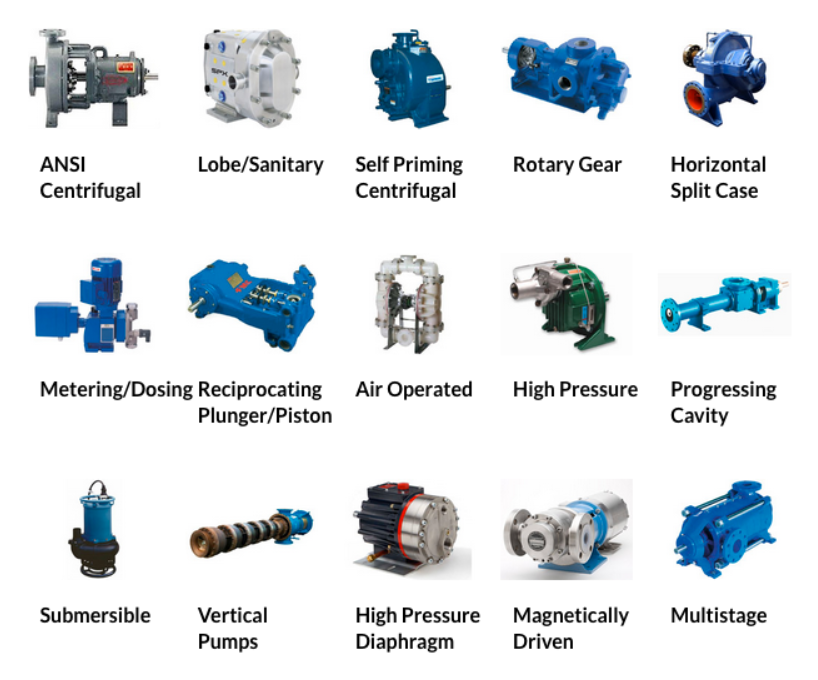

Industrial Pump Types and Their Main Benefits & Applications

There are many types of industrial pumps offered for a variety of applications. Each type of industrial pump comes with advantages not offered by other pumps. As experts in industrial pumps and rotating equipment since 1946, we wanted to provide a quick easy-to-digest way of understanding what advantages each industrial pump possesses.

Main Benefits, Advantages, & Applications of Each Type of Industrial Pump :

1. Centrifugal Pumps

The best choice for lower viscosity liquids and high flow rates.

2. ANSI Process Pumps

Incorporates dimensional standardization, which allows for the piping, foundation, and design to be completed before pump suppliers are even selected. Also features more material options than other types.

3. API Process Pumps

Meets all API 610 requirements which assures safety & reliability for high pressure, high temperature hydrocarbon applications.

4. Axial Flow Pumps

The best choice for achieving a very high flow rate with very low head.

5. Booster Pumps

Allows for the build up of additional pressure required to move liquid over long distances.

6. Piston Pumps

The best choice for applications that involve abrasive liquids.

7. Progressive Cavity Pumps

Sometimes referred to as “the pump of last resort” because it is able to handle difficult liquids that other pumps are unable to accommodate.

8. Screw Pumps

These pumps feature the highest flow rate of positive displacement pumps.

9. Gear Pumps

The best choice for clean oil applications with few moving parts & simple construction.

10. Lobe Pumps

The best choice for sanitary applications that pump viscous liquids or liquids that contain fragile solids, featuring no metal-to-metal contact within the pump.

11. Diaphragm Pumps

One of the most versatile choices handling a wide range of liquids that are sealless and can run dry without damage to the pump.

12. Vertical Sump Pumps

One of the most affordable, cost-effective sump pumps offered.

13. Vertical Turbine Pumps

The best choice for deep wells.

14. Submersible Pumps

The best choice for areas prone to flooding. Also these pumps eliminate column shaft and bearings found in column sump pumps.

15. Self-Priming Pumps

Main advantage: no need for external priming!

16. Multistage Pumps

Currently the best way to get high pressure with a centrifugal pump with lower thrust loads.

17. Magnetic Drive Pumps

No mechanical seals & are certain to be leak-free in design.

18. Horizontal Split Case Pumps

One of the least likely pumps to cavitate that features much higher flow rates than end suction pumps.